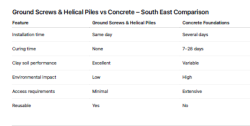

Ground screws and helical piles can be installed in hours rather than days, making them ideal for projects in:

- Residential areas of Bromley, Greenwich, Lewisham, Bexley

- Coastal and rural sites in Kent and Sussex

- Tight-access urban locations in South East London

- There is no excavation, no concrete pouring, and no curing time, allowing immediate construction.